Interest in defensive carbines has grown so much that aftermarket catalogs such as Brownells (www.brownells.com), now mail a separate issue dedicated to the AR-15 platform. But the AR is not the only available long gun and 223 Remington/5.56mm is not the only round available for self defense-for instance, theres the 7.62x39mm. This round was developed by the Soviets circa 1943. According to some loading manuals, popularity of this cartridge in the United States saw a boom when GIs returning from Viet Nam brought home Communist Bloc weapons. Since then, other more American designs have been chambered for the 7.62x39mm. For example, our test weapons were the $966 Ruger K-Mini Thirty-P/20 No. 5853, and the AR-15 style DPMS Panther 16-inch 7.62x39mm No. RFA2-762-16 carbine, $850. Pitted alongside those two guns was a Standard SKS Type 56 with an aftermarket stock, the Advanced Technologies Incorporated Fiberforce unit. The addition of a synthetic stock has become a popular choice for those wanting to modernize their SKS rifles.

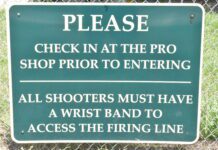

To perform our tests, we traveled to American Shooting Centers in Houston. Here we had our choice of benches facing towering berms at distances of 50 yards to 600 yards downrange. Since we would classify none of our test guns as match-grade target rifles and we would be firing with only the supplied iron sights, we set up at the 50-yard line. Our shooting team consisted of a third generation U.S. Marine on the trigger and an experienced spotter with a High Definition Swarovski Optik 10x42mm binocular to provide instant feedback without the shooter having to dismount.

For test ammunition we began with three different rounds. Winchester USAs Q3174, Federals A76239A, American Eagle, and 124-grain soft point Military Classic ammunition from Wolf. The Winchester rounds were topped with a 123-grain full-metal-jacket bullet, and the American Eagles featured 124-grain FMJ slugs. But we were forced to switch from the Wolf soft points to Wolf 122-grain copper-jacket hollowpoints to complete our tests. Both of the Wolf rounds were Berdan primed and utilized steel cases. But we found that neither of our modern guns would reliably break the primer on the soft points. The only visual difference between the two Wolf rounds, aside from the bullets, was sealant surrounding the primer of the 122-grain ammunition. In contrast, our SKS shot reliably with every type of ammunition we could find.

Accuracy data was collected by delivering 10 shots to the target. We then used a measuring technique that determined the center of the group. Our accuracy chart lists Average Group Radius, the average distance that each shot printed from dead center, Maximum Spread, the widest separation between dead center and a single shot, and Maximum Shot Radius. Average Group Radius and Maximum Spread were measured to the center of each bullet hole and these measurements express average group size and largest group, respectively. Maximum Shot Radius was measured from the furthest edge. If a circle was used to “lasso” every hit on target, Maximum Shot Radius would equal the diameter of the circle.

But theres more to a rifle than shooting from a bench. Here is what we learned.

SKS Standard Type 56 w/Fiberforce Stock,

$510 retail

All available SKS rifles are either used or surplus. The exception would be companies that offer “new” guns that are weapons assembled from spare parts. We are beginning to see AK-47s made in the USA, so as import lines dry up perhaps new production SKS rifles will be offered in the future. In the meantime, our listed price represents a common if not the higher end cost for an SKS Type 56 in very good condition, plus the cost of the stock. Advanced Technologies (www.atigunstocks.com) offers six different replacement stocks for the SKS ranging in price from $59 to $139, with options ranging from AR-15 style buttpads with adjustable length of pull to traditional rifle stocks with camouflage finish. List price for the Dragunov-style Fiberforce stock No. SKS3000 was $69. This includes an adjustable-height cheekpiece (removable), which becomes necessary for sight alignment after mounting a scope.

The original stock was wood with a metal buttplate and rudimentary sling loop screwed on to the left side of the butt. With sling in place this can be intrusive to the right-handed shooter. There was also a sling loop integral with the barrel band at the forward edge of the cylinder, which contains the piston. Both the original wood and the Fiberforce stock supply a separate handguard that covers the gas cylinder. The wood stock was coated with a thick varnish and lacked checkering. The most apparent difference between the original stock and the Fiberforce replacement stock was overall length and length of pull. The Fiberforce stock extended the SKS by almost 3 inches. The larger operators on our staff preferred the longer synthetic stock because it provided a less cramped position when lining up the sights. But the number-one reason this stock was preferred was that

it provided a vertical pistol grip with thumb-through capability.

From the bench, we found our only challenge was adjusting for windage. The front sight was permanently attached to the combination muzzle brake/flash hider. The blade itself was threaded just like a screw and could be turned down or up with the use of a dedicated tool. The front-sight blade was mounted on a heavy pin seated laterally inside the protective cowl. This pin could be shifted left or right by using a sight pusher, but movement was limited. Elevation was adjusted at the rear sight, which consisted of an open notch and blade, offering a sight picture much like a modern pistol sight. The rear sight rode forward and back on a ramp that pivoted higher and lower as a spring detent wedge was moved forward or rearward.

Our SKS rifle was loaded by way of stripper clips. When we said earlier that changing the stock was probably the most popular modification to the SKS, we might have said adaptation to removable high-capacity magazines was also high on the list. Magazine conversions are available for the SKS, but in our opinion changing from clips to mags does more to destroy the charm of this design than placing the action in even the most space-age synthetic stock. If loading by clips sounds tedious, we found that the clips were very easy to load. They held a maximum of 10 rounds, and once threaded into the clip guide (integral with the bolt), the rounds piled easily into the magazine. It was fun, too.

We found no way to lock the bolt open with a separate lever or catch. The bolt simply reacted to the empty magazine. Wishing to the close the bolt, we reached under the stock and pulled back on the floorplate/magazine release. The floorplate was hinged and fell away, along with the follower that rode on a separate axis. With the follower out of touch, the bolt willingly rode forward. But you couldnt just snap the magazine and follower back into position. We had to pull back on the release once more to seat the floorplate.

The trigger safety was another feature begging special attention. The safety was a lever about the same length and arc as the trigger. It was hinged at the upper rear corner of the trigger guard on the right side. Pushed forward until horizontal, the safety was on. Its surface was flanged outward to provide grip for rotating it to the rear where it lined up against the rear profile of the trigger guard. Can a shooter pull down the safety and accidentally (or on purpose) activate the trigger? Maybe, so be aware.

From the 50-yard bench our hybrid SKS delivered groups measuring about 0.76 inches across firing Winchesters 123-grain “Q” loads. This performance was bracketed by average group sizes of 0.84 inches firing the Wolf 122-grain hollowpoints and 0.96 inches shooting the 124-grain FMJ ammunition. The Winchester loads placed it second in terms of accuracy, behind the Ruger K Mini when the Ruger was loaded with the Wolf ammunition. But we judged our SKS to be the most consistent shooter when comparing the accuracy throughout all three (actually four) test ammunitions. As previously stated, the SKS was the only rifle to function fully with our original choice from Wolf, the 124-grain SP (soft point) ammunition. The nature of malfunction in our more contemporary weapons was the inability of the firing pin to break the primer. The indentation on the primers found on shells ejected by the SKS indicated they had been punched into submission by a mighty blow. From the drivers seat, the SKS trigger offered no discernible creep, and felt recoil was noticeably less than either our Ruger or DPMS weapons, making it our most comfortable shooter.

Our Team Said: We thought the SKS was a lot of fun, despite some features such as the safety. We like the current crop of replacement stocks, even if they run

the risk of diminishing its considerable charm. This is a trip through history no matter how you modify it. Found in good condition, these guns are utterly reliable and not at all fussy about ammunition.

Ruger K-Mini Thirty-P/20 No. 5853

7.62x39mm, $966

In our November 2008 issue we reviewed a K-Mini chambered for 6.8 SPC ammunition. Despite the mechanical success of this chambering, the 6.8 has been dropped in favor of producing two models built to fire 7.62x39mm ammunition. The only difference between the 5806 unit and our 5853 was the addition of a 20-round rather than 5-round removable box magazine.

The K-Mini soldiers forth with a black synthetic stock and stainless-steel barreled action. The Ruger website describes its “Garand-style action” as running via a breechbolt locking system with a fixed-piston gas system. Key to its appeal for us was its utilitarian nature. One creature comfort that comes standard, aside from a set of rings that lock smartly into the integral base, was a slip-on Limbsaver buttpad. This also increases length of pull by about 0.7 inches, which for some members of our staff improved ergonomics. The pistol grip, for example, was somewhat slender, and pushing the gun forward helped to straighten the strong-hand wrist.

The Ruger K-Mini Thirty-P/20 was compact. There was nothing sticking out save for the 20-round magazine. The front sight was a ramped blade between two protective ears machined as one piece including a barrel band. The unit was held in place by a roll pin, and all sight adjustments were made at the rear sight. The rear-sight unit offered a ghost ring that can be pulled left or right by loosening set screws on either side. This is not the most convenient design, but once set they provided a positive lock. Likewise, the elevation adjustment that asked the operator to rotate the ghost ring in 180-degree increments. If the method of adjustment seems crude or tedious, we dont think repeat adjustment will be necessary. Of the four different test ammunitions we tried, there was little variation in terms of velocity or bullet weight. With little difference between available 7.62x39mm ammunition, we think the supplied sights were a matter of set it and forget it.

Locking the bolt open required pulling back on the bolt and pressing down on the catch button located atop the receiver to the left of the ejection port. The owners manual said that you should be able to release the bolt merely by pulling back the bolt. But we werent always able to do it manually. Nor did installing an empty magazine guarantee the bolt would lock back. What we discovered was that these mechanical demands were better served by the force of an ignited round. When working the bolt of this rifle manually, whether to lock it back or release the bolt forward, a forceful movement was required.

We should add that properly inserting the magazine was the key to operation. Foolproof loading began by holding the magazine at approximately a 45-degree angle to the receiver. Leading with the forward edge at the top of the magazine, insert until it hits just beneath the chamber mouth. Then rotate the magazine upward until it clicks into place. Then give it an extra shove and a pull to make sure it is locked into the receiver. A visual inspection through the open ejection port should show the first round level with the bottom of the chamber mouth, but slightly offset. This is because inside the magazine, the rounds are seated one on top of another in a staggered column. Look for a properly seated magazine to present the next round directly at either the 7 oclock or the 5 oclock position of the chamber mouth.

Magazine release was quick and allowed us to control the magazine rather than let it fall to the ground.

Reaching forward with the non-shooting or support hand, wrap your fingers around the front of the magazine and let your thumb gather the release lever that hangs vertically less than one-half inch behind the magazine well. This natural gripping action lets you pluck the magazine from the gun. The only other manual control aside from the trigger was the safety. The trigger safety consisted of a panel that was pulled rearward into the radius of the trigger guard for safety-on condition. Pushing the panel forward, away from the trigger, made the gun ready to fire.

From the bench we only found one round that didnt perform well in our Ruger. The Winchester USA rounds were reliable but produced the largest groups. The American Eagle ammunition produced statistical groups that averaged about 0.85 inches across. But firing the Wolf 122-grain HP ammunition, the Average Group Radius measured just 0.75 inches across, topping our other test rifles.

Our Team Said: We liked the option of the 20-round magazine, but would definitely keep the flush fit five-round magazines on hand to preserve its slim, fast-handling profile. The sights are sturdy and adequate, but we think using the supplied scope rings to mount a variable-power scope low on the integral scope base would help this model fulfill Rugers original vision for this series-that of being a Ranch Rifle.

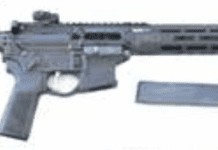

DPMS Panther 16-Inch No. RFA2-762-16

7.62x39mm, $850

Our DPMS Incorporated AR-15 chambered for 7.62x39mm included many of the familiar controls and the profile that has captured Americas heart. This meant a thumb-operated safety, right-side magazine-release button, pistol-grip stock, flash hider, combination front sight stanchion and gas block, fully adjustable rear sight protected in a carry handle, and civilian minimum legal length 16-inch barrel. Barrel twist for this caliber model was 1:10. The short carbine-length handguard was the standard synthetic part void of any rails, but vented top and bottom. The buttstock on our Panther was of traditional full profile standard A2 Mil Spec, rather than the six-point adjustable buttstock that has become so popular. In view of the increase in recoil and torque that comes with firing 7.62 ammunition, it is reasonable to assume that DPMS chose to employ a fixed stock in order to provide a more rigid platform. We suspect this also increased weight. Our Panther weighed about 7.5 pounds. Just out of curiosity we weighed a 223-caliber Panther Carbine A2 No. RFA2-PCAR-16 with adjustable stock. This carbine weighed about 6.6 pounds. If you prefer the adjustable stock, or any of the options offered by DPMS, this gun can be delivered to meet your needs.

One aspect we liked about this rifle was that it was familiar. Anyone trained on an AR-15 or a faithful 22 LR reproduction such as the Smith & Wesson M&P 15-22 (see Gun Tests February 2010), was good to go with no additional training necessary. This included takedown and cleaning. Our DPMS Panther came complete with a cleaning kit that did indeed fit neatly into the compartment inside the buttstock.)

Due to the popularity of the AR-15, we think most shooters will readily accept alternate chamberings, wherein the only difference is the level of recoil. Most people think of recoil being expressed primarily as muzzle flip. But bigger bullets in handgun and long guns alike also introduce torque as they fight against the twist in the barrel. Pistol-grip weapons such as the Panther (and the vertical grip of the Fiberforce stock) enables the shooter to pull the buttstock tighter into the shoulder. Furthermore, the vertical grip, as opposed to a straight stock, makes it easier to introduce a slight cant to counteract torque.

Our Panther was shipped with two 10-round magazines. These magazines fit nearly flush, making them ideal for shooting from a bench. Construction of the 10-round magazines was all plastic save for the springs. The basepads were removable for easy cleaning and reconstruction, but we found that the basepads could sometimes work themselves loose. We also noticed that the follower in each magazine was slightly different. In terms of locking back upon empty, one of the magazines was more consistent than the other. Wed order the 30-round magazines that feature stainless-steel bodies, anti-tilt follower, and chrome springs from dpmsinc.com for $25.

Our accuracy session showed that our AR-15-based carbine much preferred the Winchester and American Eagle ammunition over the Wolf rounds. Average Group Radius firing these loads were nearly even, measuring fractionally more than 0.80 inches across. The Wolf ammunition delivered an AGR of about 1.25 inches. One aspect that we should point out is that the Wolf ammunition utilized steel cases. Not only is this more abrasive on breeches, extractors, and chamber walls, but it can also introduce a slight change in the way the gun cycles. Brass cases expand when the charge is ignited. Steel cases expand primarily at the case mouth and little elsewhere. This expansion is all part of the timing of the weapon and can offset function and possibly accuracy, too. Some say this is only a theoretical concern, but some weapons are more sensitive to steel-cased ammunition than others.

Our Team Said: Some AR-15 owners are looking for more punch. Even the military continues to debate a new cartridge for this platform. We think 7.62x39mm itself is a good choice, but we didnt find the DPMS Panther to be amenable to steel-cased ammunition. We might also beware of surplus ammunition. This could be a disappointment to anyone expecting to save money over the cost of 223 or 308 fodder. We still like this combination, however, because the gun can be delivered with options to suit the owner. But attention should be paid to the quality and condition of the magazines.