I used to go into the deer woods with a cut piece of plastic (to sit on a wet downfall), a six-foot length of drag rope and a turkey sandwich left over from Thanksgiving. Of course, I had my knife and maybe a candy bar along with something to drink which I carried in my pockets or a small backpack. My six and half pound carbine rested in the crook of my arm instantly ready but I really didn’t think about how I would carry my rifle until I was dragging a deer about a mile back to camp while trying to shift my Model 94 Winchester from one hand to another. It soon became obvious that a good sling would be beneficial. Unfortunately, the 94s at that time didn’t come with such accoutrements and I was forced to install my own.

Nowadays, most hunting rifles have factory-installed studs for attaching the quick-release swivels favored by many hunters. Some, however, are still bare and the wood stocks we make and finish ourselves need to be so equipped. I wouldn’t dream of handing a rifle I’ve built to an excited customer without adding these small but not insignificant parts of a finished stock.

I want to stop here and enter a personal aside to this article. It’s true I think a sling is a necessity on a hunting rifle but only when the first job of the rifle, that is, putting the animal on the ground, is over. The only one time I want a sling on my rifle is when I am bringing both it and the game back to camp. An exception would be serious climbing that requires two hands also requires a sling. A sheep hunter watching his expensive mountain rifle bounce down a rocky cliff would agree with me. For other hunting pursuits I believe it’s best to have the rifle at hand. A quick shot may be needed or the opportunity lost. Whether we are hunting from good concealment where the game is completely unaware of your presence, such as a tower blind in Texas or a twenty foot high tree stand in Illinois, or still hunting the pines, (yes, some hunters do it the old fashioned way) a hunting rifle should be at the ready at all times. A sling in these cases just gets in the way.

I don’t believe it is good practice to actually hunt when your rifle is slung over your shoulder. I understand that some folks use the sling as support, such as a hasty sling. If that is your thing, OK, but I prefer to use natural rests such as tree limbs and stumps or my hat over a suitable rock. This works better for me because in my part of the woods such rests are normally close at hand. Also, I can shoot with acceptable field accuracy offhand, since I practice regularly from that position and only take shots at game that are not too far out of my self-imposed range limit. When I had a smaller waist I took my sling off when I stepped into the woods and wrapped it around me like a belt. Nowadays, it stows in the pack until I’m ready to use it. Either way, I keep my rifle in my hands.

It was a hot day for deer season in Maryland during the end of November, probably almost eighty. I was a teenager who hadn’t taken his first buck hunting and was hunting on public land. I came to a dirt road where the bank was just right for me to sit down and take a rest. I looked up the mountain where I would have to hike back to the truck as if it were the thirteen steps to the top of the gallows. I was hot, sweaty, overdressed for the heat and worn out. While considering my situation, I noticed a very nice eight point buck standing in the middle of the road thirty yards away wondering what the heck I was doing there! I grabbed for my slung rifle, the buck bolted, and down the hill another hunter dropped it cleanly. Well, that’s the way a hunting kid goes to school and what I learned about rifles that were hung over my shoulder that should have been ready to go.

In more open country a bipod or backpack may be used as a rest. Here, too, a sling just gets in the way of a fast setup. Many guides have bemoaned their hunter’s slow reaction time after spotting game that may be nervous about sensing them and ready to bolt as the hunter fools around adjusting this and that and is rewarded with a hurried shot at a bouncing tail.

Using binoculars is problematic at times while carrying an unslung rifle but I can usually manage a quick look through a 7-8 power pair with one hand. If I want to take a longer look-see, that means I have unspooked game ahead and I can sit down, putting my rifle safely aside and enjoying a rest for my glass using both hands.

Then we have so-called hunters who never set foot in the field without a guide and maybe a small safari. They’ve just bought a new magnum rifle that the guide generously agrees to sight in for them since they’ve never actually fired the piece themselves. After watching a miserable performance at the so-called sight-in (where the guide is actually measuring their client’s skill with a rifle) the guide doesn’t allow them to load their rifle until they are within spitting distance of the so-called “game.” I don’t blame him for that.

I understand there are many ways to hunt and where a sling is useful and where it is not. One thing for sure, you must have sling studs installed to match the modern swivels if you want to use a sling on your rifle and if they aren’t there, a gunsmith must install them. I did this job as a boy. Drill a hole, then screw ‘em in. What’s the big deal? I wonder how many installations I messed up. Thankfully, it wasn’t a whole lot because I soon learned that off center holes and cock eyed sling studs stuck out on a stock like a missing picket of a fence and branded you as an amateur. This job can be handled well by anyone who takes care in their work. An amateur with a good hand drill and a steady eye can do a good job but the best job is consistently done with a good tool. Without enough precision, day after day, even the best craftsman can mess up. Not enough coffee that day, a cup too many, a tiny bit of casualness for a small job in the scheme of things, who knows? But sooner or later it will happen due to human nature, usually on the most expensive stock you’ve ever had in the shop. Off-center holes drilled in the toe of fancy French-walnut are really difficult to hide.

Another place a sling is essential is target shooting. For my part I don’t get to work on many full-blown target rifles and many of the competitors have very definite ideas about how their rifles are set up, so for this discussion let’s stick to the regular hunting rifles most of us take afield.

It’s not unusual to have one of these seemingly inconsequential little pieces of metal ruin a stock or ruin a hunt if installed improperly. I had a fancy target rifle of my own mounted with a 24X Leupold target scope attached that I foolishly slung over my shoulder the first day at the range with it, only to have the front swivel stud separate from the heavy-barreled rifle stock, bending the aluminum tube of my expensive scope as it hit the ground with a sickening thud. Fortunately, the manufacturers of these quality products made things right and my world was good again.

I want my hunting rifles and heavy rifles to have the front studs bolted securely in the stock without any chance of failure. Once bitten, you know? The rear stud, of course, must be screwed in as far as it will go and then left to hope. I have Acraglased the rear studs on some of my hunting rifles but that may be overkill. One thing for sure, those suckers ain’t coming out.

There are several fixtures (jigs) available to the trade for installing sling studs and the accompanying swivels. I don’t have sales figures but at least one of these tools has been around for many years. Someone agrees with me that a steady hand may not be all that’s needed for this job.

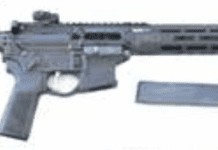

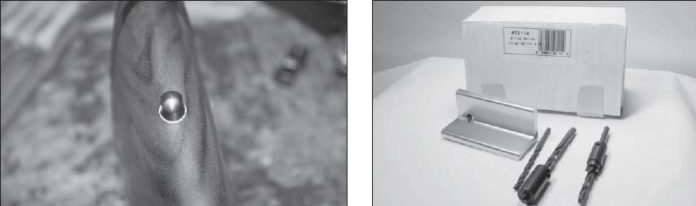

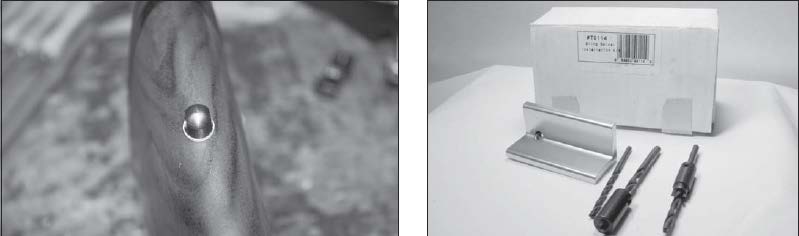

Two jigs I recommend are available through Brownells. The Kleinendorst Sling Swivel Drill Jig (488-000-006WB) is the more expensive of the two, retailing for $129.99, and the B-Square Swivel Jig and Drill Set (122-140-000WB) comes in at $54.99. Since the B-Square is the only one I have in stock at the moment, we will discuss its use in this article. This is not meant to imply one tool is better than the other. I may acquire the Kleinendorst one day, since I am a tool nut, but I can report the B-Square model works as advertised.

The B-Square swivel installation kit comes with a Swivel jig, a 5/32″ diameter pilot drill, a number 10 (0.1935) diameter safety drill and counter bore, and a 7/32″ safety counter bore.

For this installation I chose Uncle Mike’s Quick Detachable Super Swivels set number 1001-2 (Brownells 593-100-100AH.) This kit includes the rear wood screw stud, the front machine screw stud and nut, and two locking quick-release swivels. They are sized for one inch or one and a quarter inch slings. This kit is for all bolt action rifle stocks and there is another available for shotguns.

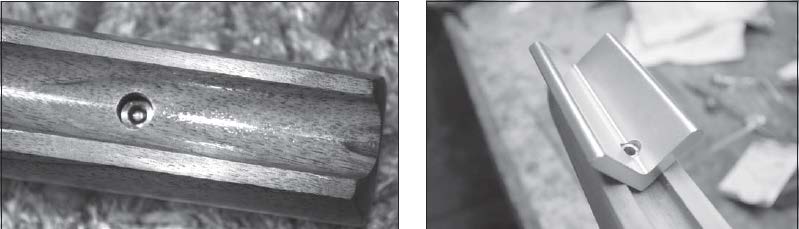

In use, the stock is leveled correctly and the B-Square swivel jig is placed in the appropriate position. The jig is equipped with a 5/32″ drill guide to keep the pilot hole straight. It is absolutely necessary to keep this hole centered and flush with the toe of the buttstock. The jig itself measures two and one-half inches from the toe for the hole. Some of us want a minimum of three inches, the theory being that anything less will eventually crack the stock. I will not enter the controversy and leave it up to each individual practitioner. The extra half inch may be more prudent for a nine-pound rifle than a mountain rifle weighing seven pounds or so.

The 5/32″ pilot drill is used to drill a hole approximately one inch deep in the toe for the rear sling stud. The 7/32″ safety counter bore is then used to provide room for the unthreaded portion of the swivel screw. B-Square recommends that the swivel screw be coated with Hoppes Linseed Oil to seal the wood and bind the fibers. It will probably keep the stud in place better than using some soap to facilitate threading it in the hole as these studs have a tendency to twist loosely in their seats after several years of use. Using a dab of Accraglas on the shank when screwing in it will stop this annoying nuisance. The stud should be aligned perfectly if the stock was leveled and a milling machine or drill press used during installation. If it does not seat level in its counter bore just a little kiss on the high side with the counter bore mounted in a hand drill will straighten it out.

The front swivel screw is a little different in that the action will have to be removed from the stock and a hole be drilled all the way through to allow a machine screw to lock up with a nut inside the barrel channel. There is no way this will pull out in normal use.

You will have to determine where to place the stud. B-Square recommends (again) 2.5″ back from the tip of the stock as measured by the jig. The jig is inserted into the barrel channel with the “V” down, which if held in place will center in the stock. Always check to make sure. The pilot hole is again drilled by the 5/32″ drill and then enlarged with the number 10 drill and counter bore. B-Square also recommends this hole be coated with linseed oil and the swivel screw nut be inserted and tapped to the bottom of the hole with a drill or punch. They then recommend putting Loctite on the screw to make sure it holds (I use the blue.) Strangely, the counter bore for the outside part of the stock for the front swivel is ignored in the directions. I just use the 7/32″ tool that was used for the rear screw. In lieu of the counter bore, little white spacers can be used and used to be very popular. Today they are not seen as much. I personally don’t care for them but it depends on the client’s taste.

Sling swivels have value in many hunting applications, but must be used at the proper time of the hunt. Otherwise they just get in the way. One problem with the studs is that even if the sling is removed the studs will interfere with shooting from the bench. You will never see a true benchrest rifle with sling studs installed. There are recessed studs available and they have a little different installation procedure. They are usually used on higher-priced rifles with a lot of fancy checkering on the bottom of the forestock, which is not conducive to a lot of bench shooting since the friction from the bags will very quickly smooth out the finest of checkering. However, with care, the studs will still allow a rifleman to sight in his piece as long as he understands the limitations.

I also think about shotgun sling installations and Uncle Mike’s does too since it has a kit that fits most modern guns. The turkey hunter could well utilize such a setup since he or she is usually sitting against a tree calling in an unwary bird. There is no need to have a sling on your gun at that point but after the bird is down being able to hang the gun over a shoulder and carrying the bird plus a lot of equipment (decoys, small blinds, etc.) makes sense.

Another area some of us may not think of is the shotgun used exclusively for squirrel hunting. I guess most of us use the same gun for upland game but I have an old single shot twelve gauge that I am partial to when it comes to beating around in the mountains trying to find gray squirrels. That gun was left to me by a beloved relative and I have piled up a truckload of those furry creatures with it. Now, I often scout the woods during the early seasons so I can put my grandsons on a hot spot and carry that old gun just to have it along.

In my neck of the woods a ruffed grouse can scare the hell out of you by exploding from a berry patch and drumming up out of cover as you pass, giving you a turn-around-quick or miss shot. I can remember wishing I could sling that gun over my shoulder for the long hike back to the truck. I might go ahead and install some swivels so I can put one on it this year. AG

Click here to see American Gunsmith’s Website

Click here to subscribe to American Gunsmith