A trigger shoe is an accessory that fits over the front of the trigger providing a wider contact area for the trigger finger. The shoe is typically made from metal and features vertical grooves to improve the “feel” during the pull. Some shooters believe the increased contact area reduces the perceived pull, while others simply like the fact that it helps position the point of pull directly opposite of the finger nail base. Trigger shoes are normally used on competition rifles and, to a lesser degree, pistols. While the benefits of a trigger shoe certainly applies to hunting rifles and pistols, the extended width of the shoe increases the chances of an accidental discharge, which outweighs any of the benefits.

288

Trigger shoes must be fitted to the specific gun. The trigger width and radius are specific dimensions that help to determine the proper shoe size. Additionally, the shoe should be slightly thinner than the trigger guard for safety and must be relieved to allow for full travel, including enough over-travel to easily remove the bolt in rifles fitted with this type of mechanism. Because the trigger shoe is wider than the trigger, the shoe must be designed for easy removal and installation to allow the trigger to fit through the slot in the floorplate when the action is removed from the stock. This is typically accomplished by means of two or three small set screws on the side of the shoe opposite the trigger hand. Trigger shoes are often made from aluminum, brass, steel, stainless steel, and even titanium. Obviously the last three materials provide excellent strength assuring many trouble-free disassembly/reassembly cycles. Brass and aluminum shoes should be fitted carefully to avoid stripping the fine threads or bending the shoe with excessive screw torque.Commercial trigger shoes are available through specialty catalogs and online stores. The user can select from a list of common rifles, and sometimes materials, based on specific needs. In the event the desired rifle model is not listed, the buyer can measure the trigger width and radius and look through the list for a close match. Measuring the trigger width is straightforward but accurately measuring the radius takes more care. Often a close match can be found by trying different sized coins or washers, and then measuring the coin or washer diameter using micrometers. Special care should be taken with this technique to observe the shape of the trigger outside of the contact area and make sure it will not interfere with fitting the trigger shoe. In the event no catalog shoe can be found, many stores will offer custom trigger shoe fabrication given the information above. Cost will depend on the popularity of the shoe as well as the material. In my experience, this ranges from $40 to $60 and up.Recently, I decided to fit a trigger shoe to a Remington Model 33 Youth Rifle, a .22 Long Rifle single shot bolt action, for my 10 year old son who is participating in a Junior Rifle program at my club. The Model 33 is a lightweight rifle that he can handle comfortably through several hours of prone shooting. This rifle was made between 1932 and 1935 in relatively small numbers but not small enough to warrant a high price for rarity. I bought it years ago as a training rifle for less than $150. I could not bring myself to spend 20 to 30% of the gun’s value on a custom trigger shoe, so I decided to make my own.

288

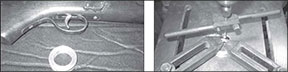

The first step in machining a trigger shoe, or almost anything else, is to determine the design. This process involves measuring the rifle’s trigger diameter, which will determine the diameter of the bar stock required, trigger width, which sets the proper slot dimension, and the trigger guard width. The width of the shoe must be the same or smaller than the trigger guard for obvious safety reasons. The final dimension is a matter of preference but careful thought needs to be given to the design for this decision. Remember, the trigger shoe is held in place by small set screws on one side. These set screws will be about 3/32 of an inch in length. For the set screw to lie flush or below the trigger shoe surface, the shoe will need to be at least 3/16″ wider than the trigger. The trigger guard on most non-military rifles is only two times the thickness of the trigger and the trigger is generally around 1/8″ wide. As a result, the trigger shoe will be only slightly smaller than the trigger guard in most cases.Measuring the trigger is best accomplished by either removing the action from the stock or removing the trigger guard. The width of the trigger is easily measured with calipers. My Model 33 has a trigger that is 0.175 inches wide. Measuring the trigger radius is a bit trickier. For those of us who have not invested in a set of large radius gauges, I think the easiest method is to estimate the radius using coins. Quarters and nickels are a pretty good starting point. In my case, a quarter was close to the right dimension. Then find a few washers that are a bit smaller and bit larger than the closest coin.Hold each up to the trigger with a bright surface behind. If the washer is too small, you will see light on either side of the contact point. If the washer is too large you will have two contact points with a crescent of light in between. Once you have found the washer with a minimal gap, simply measure the diameter with calipers. The Model 33 measured 1.24 inches here. The largest diameter of the trigger guard should cover the trigger. This required an outer diameter of 1.54 inches in my case. The inner diameter should be small enough to allow serrations to be machined on the business side of the guard but not so small as to limit the amount of room for the trigger finger within the trigger guard. I decided on a 1.00 inch inside diameter.Now measure the width of the trigger guard using the calipers. I measured the width just forward of the trigger position. My Remington measured 0.380 inches. This determines the maximum width for the trigger shoe. I decided to use two 6-48 x 1/8 inch long set screws to hold the trigger shoe in place. Like many firearm applications, the trigger shoe has a relatively short distance for the screws to engage. In order to have a reasonable number of threads, the thread pitch is larger, or finer, than standard screws. Most number 6 machine screws have 32 threads per inch but for this type of application a 40 or 48 pitch screw is better suited. I settled on a 0.38 width, which leaves just over 0.10 inches for the set screws to make sure they mount slightly below the surface. I looked through my collection of cutoffs for a suitable piece of bar stock and settled on a hollow brass bar with an outside diameter of 1¾ inches and a ½ inch bore. After cutting the stock down to a reasonable length, the lathe work began with finishing the inside diameter to an even one inch using a boring bar. The outside diameter was turned down to 1.54 inches and a notch was carefully cut to a diameter of 1.24 inches and a width of 0.175 inches. The notch must be positioned in the center of the trigger guard, so it is important to measure carefully.

288

The last step for the lathe is to make vertical serrations on the inner diameter of the trigger shoe. This was accomplished by using the boring bar with a 45 degree pointed tip to cut into the shoe. I used five serrations so the middle cut occurred halfway into the trigger guard, or 0.19 inches. The lathe carriage should be carefully positioned and then locked in place for this operation. The depth of cut will determine the width of the serration, in fact, these numbers will be equal for a 45 degree cutting tool. I wanted a small flat between the minor, or smallest, diameter of the serrations, while leaving a small flat between the outermost serrations and the edge. The carriage was indexed in increments of 0.060 inches for each cut. The shoe was then polished using emery cloth before being cut off to the final width.After marking the left side of the trigger shoe (for a right handed shooter) with machinist blue, the overall shape of the shoe was marked along with the desired placement of the set screw holes. The centers of the holes were placed between the outer and groove diameters at a distance of 0.10″ from the ends. The piece was then clamped and positioned in a drill press vise. To assure an evenly tapped hole, the entire sequence of spot drill, drill and tap should be completed without moving the part. Tapping is best done with a tap guide, which holds the tap perfectly in line with the drill spindle while applying a force to help start the tap. Proper alignment is especially critical with a fine pitched tap. After tapping, a modeling file can be used to remove any small burrs from the inside edge.The trigger shoe can then be cut off from the turned piece either in a milling machine or by hand. I chose to use an abrasive wheel. The final shape was accomplished with a file. To avoid scratching, remember to card the file regularly to avoid buildup of chips. Once contouring is complete the shoe can be buffed using a felt wheel and compound. This requires a delicate touch with brass as it is easy to remove too much material, not to mention generate too much heat!The trigger shoe is now ready to be mounted. Once fitted, make sure the trigger has sufficient travel to drop the hammer and, for some guns, to easily remove the bolt. This may take several sessions with the file and buffing wheel. Remember to use a soft touch with the hex wrench when tightening the screws to avoid stripping the threads. If a thread lock is to be used be sure to select a removable type made for small screws. The trigger shoe will eventually have to come off to remove the action from the stock, so don’t make the assembly permanent. A proper fitting wrench can be carried with the shooting supplies in case the set screws become loose at the range.Making your own trigger shoe requires careful planning and machining but can be accomplished over a weekend. Remember to plan ahead and have the raw material and set screws on hand before finalizing your design. The custom trigger shoe will add a nice touch to your favorite target rifle and can help to tighten groups through improved trigger control. AG

Click here to see American Gunsmith’s Website

Click here to subscribe to American Gunsmith