The velocity of a bullet is a function of the pressure behind it, or the chamber pressure. Higher pressures develop higher velocities. That’s why a .30-06 shoots faster than a .30-30. Velocity is also a function of the length of time that the pressure is applied. A longer barrel shoots faster because the bullet stays in the barrel longer. That’s also why slower burning powders develop higher velocities. The hot gases generated by the burning powder push on the bullet for a longer period of time.

Chamber pressures are generally limited by the brass case to 65,000 psi (52,700 cup), although we’ve never tested a commercial load that “hot.” Belted cases may withstand a little more pressure than rimless cases, but the commercial loads we’ve tested weren’t loaded to any higher pressures than the rimless cases. The big magnums shoot faster because they use slower burning powders. These powders require the extra room that belted cases provide. The gradual increase in velocities since the introduction of smokeless powders is due more to slower burning powders than higher chamber pressures.

This series of tests is designed to help the handloader select a slow-burning powder to match his choice of case and bullet.

What We Tested

We tested all of the slow-burning gun powders we could find with one exception. Hodgdons’ H-870 was deliberately left out of the test. Previous testing has shown that this salvaged powder varies too much from lot to lot to be predictable. With one lot, the pressure gradient, the change in pressure per change in quantity of powder, was dangerously high.

Nine different powders, including the new Alliant Reloader 25, were included in this test. We also tested with all of the different 160-grain hunting bullets we could find, thirteen in all, including the new Nosler Partition Gold. Only three rated special precautions—the Barnes X, the Nosler Gold Partition, and the Professional Hunter’s Star. We left target bullets out of the test because target shooters aren’t generally interested in the maximum muzzle velocities that these powders produce.

How We Tested

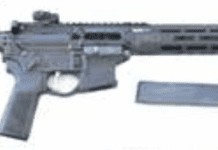

These powders were tested by actually shooting them, and recording the pressures and velocities. Pressures were measured with a peak holding pressure transducer driven by an external strain gauge. Measuring the pressure of each shot also allowed us to work up to higher than normally acceptable pressures. We don’t think you should load in the 65,000 psi (52,700 cup) range if you can’t measure pressure. Velocities were measured with an Oehler Model 35 chronograph, actually two chronographs set up to monitor each other. Shooting was done with a Ruger No. 1 single-shot rifle and a Remington Model 700 bolt-action rifle.

Both pressure and velocity values were plotted against the grains of powder required and a pair of curves was drawn. These curves averaged the variations in the data and were used to calculate the “effective burning time.” (See “How We Rated” for a definition.) Note that the burning time was not a constant, but decreased with increasing pressure. At higher pressures, the powder burned more efficiently and thus faster.

The pair of curves shown for Reloader 22 powder and the Speer Mag Tip bullet are also typical for the following bullets: Sierra’s Game King, Nosler’s Solid Base and Partition, Speer’s Grand Slam, and Trophy Bonded’s Bear Claw. Four other bullets—Hornady, Barnes Original, Hawk and Jensen—slide down the barrel just a little easier and need a grain or two more powder to reach the same pressures.

An explanation of how we rated the powders is included toward the end of this article.

The Results

Hodgdon H-4831. This old favorite was the first of the present slow burning powders, but it has been gradually superseded by slower powders. It was the fastest burning powder in this test. Our Rating: Superseded.

DuPont IMR-4831. Our testing has shown this powder to be a little slower than the above 4831, although the rating tables in handloading manuals show it to be faster. The difference was due to the testing methods used. We actually fired the powder in a rifle. Nonetheless, H-1000 was a slower powder that took up no more room in the case. Our Rating: Superseded.

Hodgdon H-450. If you need a ball powder, this is your first choice. It compresses uniformly throughout the load and won’t bulge your case. Unlike AAC-8700, you won’t have a problem getting enough powder into the case. Our rating: Good. Alliant Reloader 25. This new powder was a disappointment. Until now, Reloader powders have been numbered with a higher number designating a slower burning powder. But, this powder burns 10 micro-seconds faster than Reloader 22. We don’t see any use for it. Any of the four slower powders listed below will give you more velocity and take up the same or less room in the case. Either of the two faster powders listed above will generate higher velocities at 60,000 psi. Our Rating: Unnecessary.

Hodgdon H-1000. If you’re trying to load a light magnum, like an ’06, this is your first choice. It takes up less room in the case than comparable powders. Our Rating: “The” light magnum powder.

Norma MRP. This powder requires just a little more room in the case to produce the same velocity as the above powder. Nevertheless, it’s a good choice of powder. Our Rating: Good.

Alliant Reloader 22. Slower than MRP, but requires more room in the case than any of the other 65,000 psi. powders in this test. If you can’t reach the 85 percent loading density with your first choice of powders, try this one. It will fill the space a little better. Our Rating: Good and bulky.

DuPont IMR-7828. This powder produced the highest velocities of the test, but didn’t require the most room in the case. Our Rating: Best of Test.

Accurate Arms 8700. This was far and away the slowest burning powder of the test, and it was an easily metered ball powder. The problem is that you probably can’t get enough of it into your case, at least we couldn’t. But, if you have a bigger than normal case, give it a try.

We filled the magnum case brim full of powder that was settled by rapping on the case, and seated the bullet slowly. Compression didn’t bulge the case, as it might have with an extruded powder. We only got 3,050 feet per second with this load, but that’s a higher velocity than any of the commercial loads we’ve ever tested in this caliber. Pressure was a mild 55,000 psi. If you’re satisfied with less than maximum velocities, this should be your first choice. We don’t see how you can get into trouble with it. It’s hard to load either too much or too little. No problem with Secondary Explosion Effect (this term is explained in the next section of this article), and no need for a pressure transducer. Our Rating: Beginners Choice, Good for experts, too.

Bottom Line

We can’t pick any one powder that’s best for all loads, just three that needn’t be considered. It depends on how much room you have in your case (loading density) among other things. AAC-8700 is surely the safest and slowest, while DuPont IMR-7828 produces higher velocities without the loading density problem.

How We Rated

We rated these slow-burning powders by their burning time. You can’t actually measure the burning time of a gun powder. It starts with primer ignition and continues long after the bullet has exited the barrel. At night, you can see powder burning as it leaves the barrel.

We coined a new term “effective burning time” to rate these powders. It’s the time the powder would have to burn to produce the resulting bullet velocity if peak pressure prevailed throughout the entire burn time, neglecting losses in the barrel. Actually, it’s just the modified ratio of velocity to peak pressure. T = V/P x M/A. T is the burning time, V is the velocity, P is the peak pressure, M is the mass of the bullet (grains), A is the cross-section area of the bullet. While it’s not a time in the sense that it could be measured with an oscilloscope, it gives us a means to compare these slow burning powders to each other. The most efficient powder has the longest burn time, and produces a maximum of velocity for a given of pressure.

Conventionally, the burning rate of gun powder is determined by burning just enough of it in a closed container to develop a given pressure. The more powder, by weight, required to reach that pressure, the slower burning the powder is considered to be. Results of these tests are usually given in handloading manuals without any quantitative data, just listed in sequence in a table. That doesn’t give us any idea of the velocities expected while the “effective burning time” is directly proportional to velocity.

We have found that more powder, by weight, doesn’t always mean that the powder burns slower. Some powders further up on the scale (faster) have given us more velocity at a lower peak pressure than the so-calculated slower powders. We also need to know the relative values, how much slower or faster a powder burns. For these reasons, we have developed our own scale of powder burning speed. We rated these powders solely on their burning time. They are listed in the summary table from fastest to slowest. We didn’t report the cost of any of these powders because it’s too small, on a per round basis, to consider.

Another problem with some rifle powders is their bulk. With such powders, there isn’t enough room in the case to get enough powder in to produce the desired pressure. The specific density is too low. With others powders, the case isn’t filled full enough. We didn’t take this parameter into consideration in our rating, but we did list it in the summary table.

The specific density of the powders is provided in the summary table to help determine your loading density, or how full of powder your case is. First, determine the volume of your case with the bullet seated to its proper depth. An easy way to do this is to seat a bullet in a resized, unprimed case and fill the case with a measured amount of water. Use a 10 or 12 ml syringe to inject the water through the flash hole and measure the water required with the milliliter scale on the side of the syringe. (Buy your syringe at a veterinary supply shop rather than a drug store. It will be cheaper and won’t have a Luer lock to get in the way.)

To find the loading density, first find the volume of your powder charge by multiplying the weight of the powder by its specific density. (See the summary table for the specific density.) Next divide the powder volume by the case volume. If your loading density is more than 1.00 (100 percent), you are compressing your charge. With AAC-8700, some compression may even be useful. But, if your loading density is less than 85 percent, you may have another problem. It’s called Secondary Explosion Effect, and is due to too little slow burning powder in the case. It’s caused by a sort of shock wave developing local high pressure zones in the case. That’s why the loading manuals specify minimum loads of these powders.

The specific densities given in the summary table are with the powder settled as much as possible in the case. Using a funnel as a hopper will give you the least compaction. A two foot metal drop tube under your loading funnel will help compact the powder, a plastic tube won’t help at all. Pouring the powder on the side of the funnel so the powder can swirl as it goes in will do almost as much good as a drop tube with much less fuss. You can settle it the rest of the way by holding the funnel on the case with one hand and rapping the case with your powder pan. If your powder load needs a little more volume to reach the 85 percent loading density, just don’t settle it.

Compressing the powder a little as you seat a bullet won’t hurt much. That crunching sound you hear with extruded powder is not, to any extent, powder granules being broken. Previous testing has shown that, for the most part, the powder granules are just being dented. While broken granules burn faster, and thus increase the burning speed, there aren’t enough of them to make a practical difference. But too much compression can bulge the case just below the shoulder because most of the compression takes place in the first half-inch below the bullet. You may not be able to completely chamber a bulged case, and it will probably stick in the chamber if you do. Ball powders (H-450 and AAC-7800) don’t have this problem. If you compress them slowly enough to allow the balls to realign themselves, the compression will be distributed uniformly throughout the case.

Seating the bullet at the cannelure may not always be a good idea. Allowing a little freebore, room for the bullet to advance before it hits the lands, helps a gun digest these slow burning powders. But, if you work up a load with freebore, it’s important that you never let the bullet extend out far enough to touch the lands. That would develop way too much pressure. Thus, it’s important to know just where land contact occurs.

We have previously tested two tools that make this measurement. The RCBS Precision Mic proved to be unsatisfactory. It substitutes a generic bullet for the one you’re using and it’s not a close enough match. The Stoney Point O.A.L. Gauge is a better tool, but it substitutes a generic unfired case. That doesn’t work very well either, unless you are loading unfired cases. Fortunately, you can use your own cases. Stoney Point will drill, tap and expand the mouth of one of your fired cases for less than the cost of the tap. With this modification, it’s an accurate tool.

The procedure of measuring land contact by partly seating a bullet in an unprimed case and forcing it into the lands by closing the action on the case has two problems. First, the bullet is usually forced too deeply into the lands. Second, it may stick in the lands and pull part way out of the neck when you eject. Our chief tester eliminates both of these problems by first expanding the mouth of an unfired case by seating and pulling a bullet several times. It should be expanded enough to allow the bullet to be inserted and removed by hand. The inside of the neck is then coated with a thin layer of quick-set epoxy and the bullet is seated in the rifle with the usual action-closing procedure. Be careful not to get any epoxy on the outside of the case. Leave the dummy round in the action until the epoxy has completely set. It can then be used to set up your bullet seater. The bullet in the dummy round won’t get pushed any further into the case by the bullet seater, because epoxy is a strong bonding agent.